Understanding the Science Behind Your Daily Drive

When you sit behind the wheel of your car, you likely don’t think about the thousands of microscopic interactions happening under the hood. You simply feel the responsiveness of the steering, the smoothness of the acceleration, and the reliability of the brakes. This seamless connection between driver, machine, and road is no accident—it is the result of precision engineering. At Global Denso Products, we believe that understanding these components helps you become a more informed owner and a safer driver.

Precision engineering refers to the design and manufacture of components with incredibly tight tolerances. In the automotive world, this means parts are built to fit and function with sub-millimeter accuracy. This level of detail isn’t just for luxury racing vehicles; it is the backbone of modern mobility that ensures your daily commuter stays efficient and predictable.

The Tangible Impact of Precision Components

How does a high-quality fuel injector or a perfectly balanced rotor actually change your commute? It comes down to the feedback loop between the vehicle and the driver. When components are engineered with precision, they communicate more clearly with the vehicle’s central computer and, ultimately, with your hands on the wheel.

Enhanced Steering and Handling

Your connection to the road is most felt through the steering system. Precision-engineered steering racks and suspension components ensure that when you turn the wheel five degrees, the car responds exactly as expected. Lower-quality parts often have “play” or a slight delay, which can lead to driver fatigue as you constantly make micro-corrections to stay in your lane. A precision-tuned system offers a crisp, intuitive feel that makes driving less of a chore and more of a pleasure.

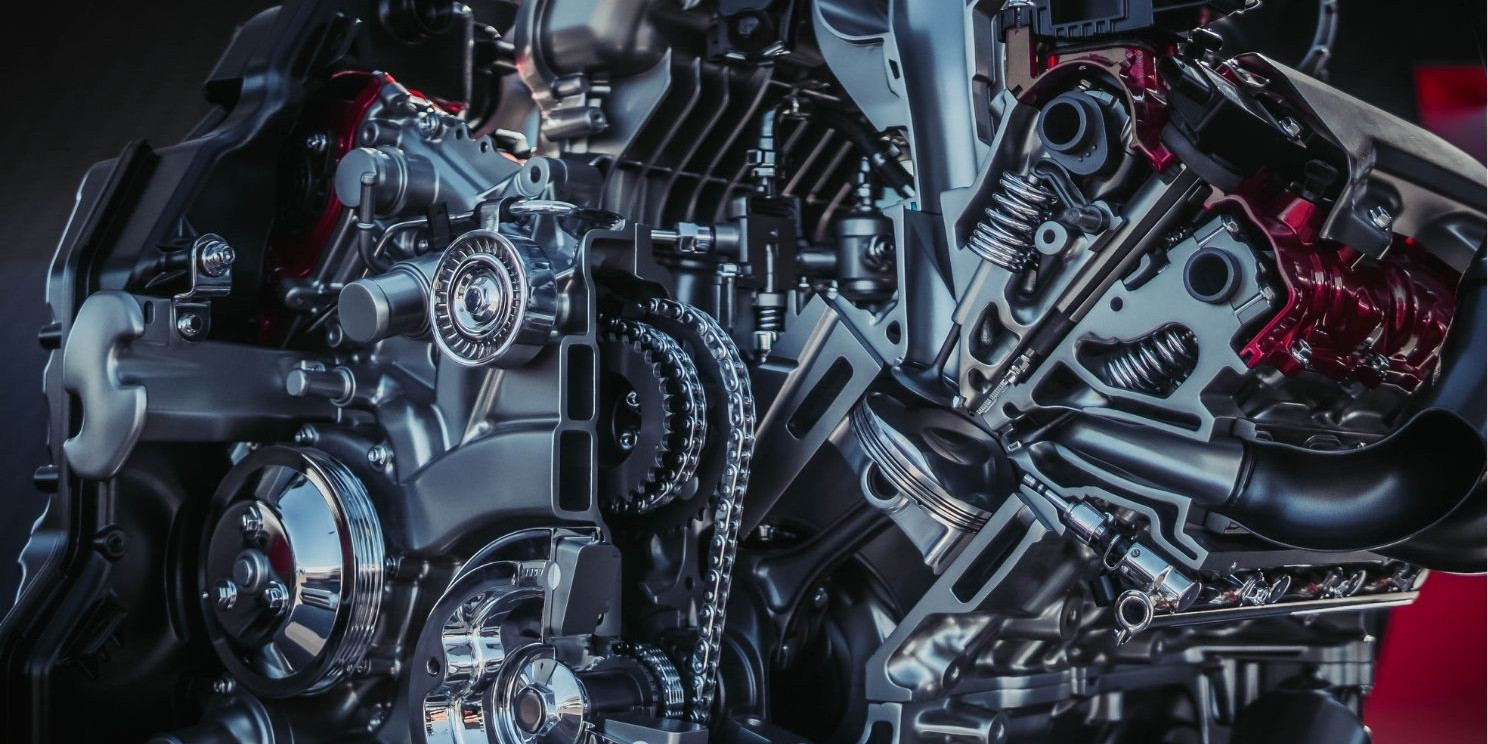

Fuel Efficiency and Engine Performance

Precision is vital inside the combustion chamber. Modern engines rely on high-tech sensors and fuel delivery systems to maintain the perfect air-to-fuel ratio. Even a tiny deviation in the timing of a spark plug or the spray pattern of a fuel injector can lead to wasted fuel and increased emissions. By using components built to exacting standards, you ensure that every drop of fuel is converted into movement, keeping your costs down and your engine running cooler.

Why Precision Matters for Vehicle Longevity

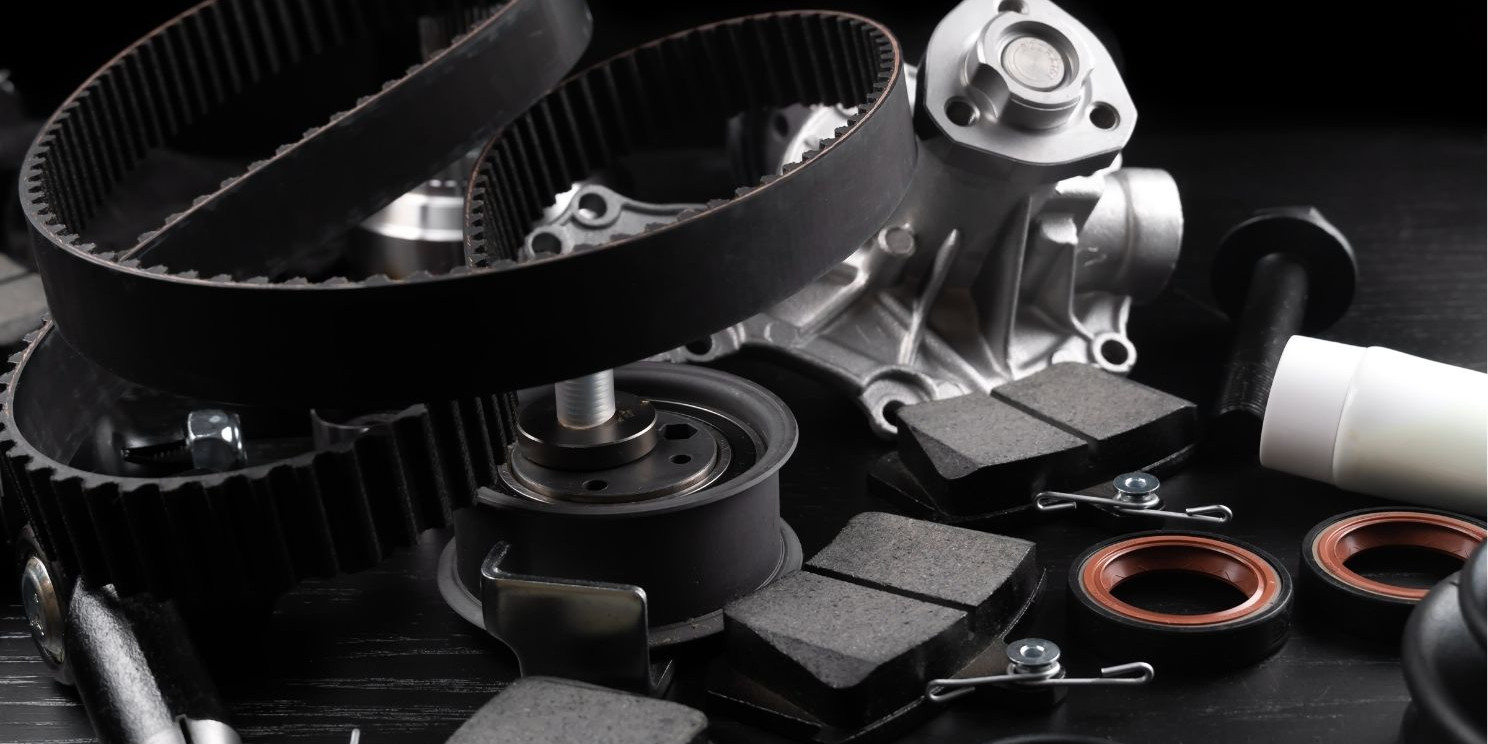

One of the most practical reasons to care about precision engineering is its impact on your wallet over time. When one part of a vehicle is slightly out of alignment or manufactured to lower standards, it creates a ripple effect. Vibration from an imbalanced component can cause premature wear on bearings, seals, and joints.

Think of your car as a finely tuned orchestra. If the violin is slightly out of tune, the entire performance feels off. In a car, this “discord” manifests as heat and friction—the two greatest enemies of automotive longevity. Precision-engineered parts fit perfectly, reducing unnecessary friction and extending the life of the entire system.

Practical Tips for Maintaining Your Car’s Precision

Maintaining that “new car feel” and a strong connection to the road requires a proactive approach to maintenance. You don’t need to be a mechanic to keep your vehicle’s precision intact. Here are a few actionable steps you can take:

- Prioritize OEM-Quality Parts: When it’s time for a replacement, choose components that meet or exceed Original Equipment Manufacturer (OEM) specifications. These parts are designed to work in harmony with your vehicle’s existing systems.

- Don’t Ignore Minor Vibrations: If you feel a new shimmy in the steering wheel or a pulse in the brake pedal, have it checked immediately. These are often early signs that a precision component is wearing out.

- Stick to the Fluid Schedule: Precision parts like fuel injectors and hydraulic steering systems rely on clean fluids to function. Regular oil and fluid changes prevent debris from damaging sensitive surfaces.

- Check Your Tire Pressure Monthly: Your tires are the only point of contact with the road. Proper inflation ensures that the precision-engineered suspension can do its job effectively.

- Monitor Your Dashboard: Modern cars use sophisticated sensors to monitor precision. A “Check Engine” light is often the car’s way of saying a component is no longer operating within its engineered tolerance.

The Evolving Connection: Mobility and Precision

As we move toward electric vehicles (EVs) and autonomous driving features, the role of precision engineering is only growing. Advanced Driver Assistance Systems (ADAS) rely on cameras and radar sensors that must be calibrated to the millimeter. In this new era of mobility, the connection to the road is facilitated by digital precision as much as mechanical precision.

By choosing high-quality components and staying diligent with your servicing, you aren’t just maintaining a machine; you are preserving the safety and enjoyment of your journey. Precision engineering is the silent partner in every turn you take, ensuring that the road ahead is always within your control.

Conclusion

Redefining your connection to the road starts with a respect for the components that make movement possible. Whether it’s the spark that starts your engine or the sensors that keep you in your lane, precision is the difference between a car that just runs and a car that performs. Stay mindful of your vehicle’s needs, choose quality over shortcuts, and enjoy the confidence that comes with a perfectly engineered ride.